MDF Rose Engine Lathe

Overview

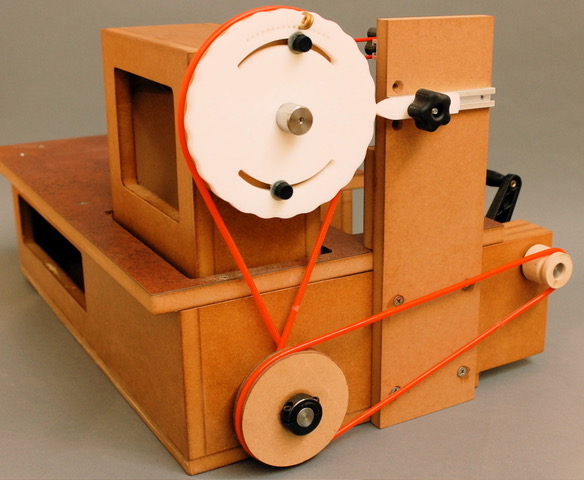

In 2007, Jon Magill designed a Rose Engine lathe using half (½) a single sheet (4 ft. x 4 ft. x ¾ in. sheet) of medium density fiberboard (MDF).

An update to the original design, known as the MDF Rose Engine Lathe 2.0, was published in 2020. The designs, along with a number of other user manuals, are all available at the MDF Rose Engine Lathe 2.0 Library (https://mdfre2.colvintools.com).

The MDF Rose Engine is oftentimes how people get started in this craft / hobby. This machine may look pretty basic, but don't be fooled. There are some very awesome aspects to this machine.

Two rosettes can be mounted onto the headstock for driving motion. These rosettes can be used together for forming a complex form (i.e., one rubber can be disengaged whilst the other is engaged). The picture to the right shows how, as the two rosettes (one red; the other blue) rotate together, the rosette driving the cutting will change from the blue rosette to the red rosette, and back. Every revolution will engage the blue rosette twice, for about 20° of the rotation each time.

These rosettes can also be phased relative to each other. Using the picture to the right again, the red rosette has 36 lobes, so rotating it 5° relative to the blue rosette would produce a wave-like pattern. This is a feature that I've only seen on this machine. The typical approach is that many rosettes are secured together as a barrel, and all are rotated together, not relative to one another.

There are many of these machines in use, and thusly, there is also a huge user community driving constant innovation.

The machine was initially designed for rocking motion, but a number of great approaches have been implemented for adding pumping motion -- whilst using the same rosettes. (Typically, pumping is implemented using the face of the rosette, not the edge.)

|

|

The machine was also designed to have the object be rotated by a hand crank (the little black handle in the picture to the left). This works acceptably and does allow for slow rotation which can be useful during the final passes; however after a while it can get a bit tedious.

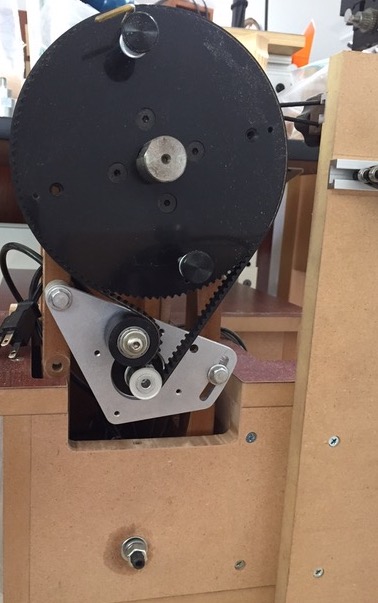

At the 2018 Ornamental Turners International Symposium, three different demonstrators showed their MDF Rose Engines, and all three showed how they had modified their machines to use stepper motors and a very sophisticated drive mechanism based on the Teensy Microcontroller (a variation of the Arduino controller).

This provides for spindle rotation using a motor which has a wide range of rotational speeds, and slower speeds don't sacrifice torque, as is seen with variable frequency drives. My machine will run as slow as 4 minutes / revolution (yes, that is "mpr", not "rpm").

If you are thinking of going this route, check the MDF Rose Engine Lathe 2.0 Library. There is a manual there, "Instructions for Building Stepper Controls System" with directions for building one. And Colvin Tools can provide you parts.

Interesting side note: Since converting my MDF rose engine lathe to use stepper motors, the quality of my cuts have gotten significantly better (i.e., smoother). My supposition is that this is due to the more even, steady rotation of the spindle.

Jon discusses stepper motors in the video below from the 2018 Ornamental Turners International Symposium.

|

|

ELFOS v3 Splash Screen

There are a number of approaches for controlling the stepper motors, and these are outlined in the Automation page.

One of note is the ELFOS system which is programmed to make this system a great tool for the artist. Fear not though: the complete user manual for this system is online at the MDF Rose Ehgine Lathe 2.0 Library, and includes a whole host of information on how to use the system to achieve the desired artistic effects. The programming efforts for this are come from Edward French, an awesome programmer who is posting his efforts on GitHub in the RoseEngine_SpindleAndAxis project.

Similar drive mechanisms have been used for implementing a leadscrew. This leadscrew movement can then be used to implement a curvilinear slide type of movement.

On the forum for the Ornamental Turners International (OTI), George Balock noted in the MDF Rose Engine section that he was able to acquire rosettes from Wade at Mandala Rose Works which were created especially for the MDF rose engine, including the phasing holes and hold-down screws. Please note however, that the rosettes I have from Mandala Rose Works are ¼ in. thick (vs. the ones provided by Jon Magill which are ½ in. thick). This is probably not an issue when using these rosettes for rocking; however, the ½ in. thick ones are needed if pumping is to implemented on the machine.

Usage Notes

The User Manual is available on-line.

Notes on making one

The MDF Rose Engine 2.0 Library provides manuals which describe the details for building one. The key manuals are:

- MDF Rose Engine Lathe 2.0 with Stepper Motor Drive

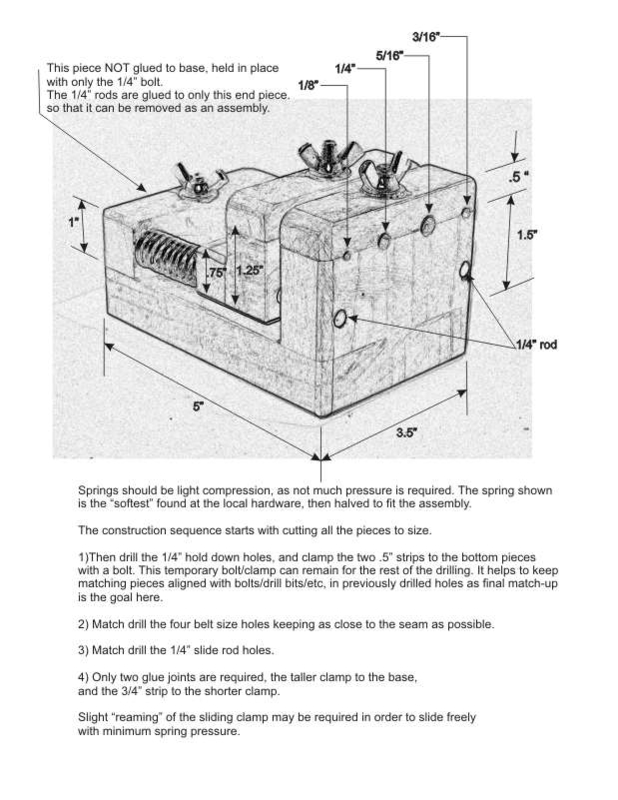

It is recommended that a new machine be built with amplitude adjusters from the get-go. These are quite useful.

|

|

Automation of the spindle drive is also needed. The manuals for the known approaches for this are:

- Spindle-only drive

- Control System for Spindle Stepper Motor Drive - Instructions for Building

- ELFOS Control System for Multiple Stepper Motors

|

|

Some additional information is available about this machine on the Rose Engine Approaches page.

Notes on making parts for one

The MDF Rose Engine 2.0 Library provides manuals which describe the details for building one. The key manuals are:

- MDF Rose Engine Lathe 2.0 with Stepper Motor Drive

- Jigs, Fixtures, & Add-ons, Volume 1

- Amplitude Adjusters

- Rosette Phaser/Multiplier

- Jigs, Fixtures, & Add-ons, Volume 2

- Curvilinear Slide

- Jigs, Fixtures, & Add-ons, Volume 3

- Spherical Slide

- Jigs, Fixtures, & Add-ons, Volume 1

|

|

The User Manual also has documentation about the standards around which the machine is designed. This can be useful if you want to design your own parts.

More Information

Published Articles

- Amplitude Adjuster for an MDF Rose Engine, by Rich Colvin. Ornamental Turners International Newsletter, Volume 26, No. 2 - Winter, 2019, pg. 23

- Build an Overhead Drive, by Jon Magill. American Association of Woodturners' "American Woodturner", Spring 2008, Vol 23, #1, pg 30

- The Cutting Edge of OT, by Jon Magill. American Association of Woodturners' "American Woodturner", Spring 2008, Vol 23, #1, pg 30

- Cutting Through the Layers, by Jon Magill. American Association of Woodturners' "American Woodturner", Spring 2008, Vol 23, #2, pg 55

- It's a Small World, by Jon Magill. American Association of Woodturners' "American Woodturner", Spring 2007, Vol 22, #1, pg 40

- Ornamental Obsessions - Slightly Eccentric, by Jon Magill. American Association of Woodturners' "American Woodturner", Fall 2009, Vol 24, #3, pg 60

- Ornamental Snowflakes, by Jon Magill. American Association of Woodturners' "American Woodturner", Winter 2008, Vol 23, #4, pg 34

- Phasing Fundamentals, by Jon Magill. American Association of Woodturners' "American Woodturner", Fall 2008, Vol 23, #3, pg 62

- Rose-Engine Turning, by Jon Magill. American Association of Woodturners' "American Woodturner", Spring 2007, Vol 22, #1, pg 46

- What is Old is New Again: A History of Contemporary Ornamental Turning, by Jon Magill. American Association of Woodturners' "American Woodturner", February 2016, Vol 31, #1, pg 38

Web Sites

- 3D-printable Enclosure for 4.3" Nextion Display

- 3D-printable Enclosure for 7" Nextion Display - The 7" display is recommended

- ELFOS Code on GitHub

- ELFOS V3 User Manual

- MDF Rose Engine 2.0 Library

Presentations

- MDF Rose Engine Basics (YouTube video) by Jon Magill.

- MDF Rose Engine Pumping Mechanism (YouTube video) by Pat Miller.

- Ornamental Turning on an MDF Rose Engine (YouTube playlist) by Rich Colvin.

- Original MDF Rose Engine Lathe

- MDF Rose Engine Lathe 2.0

- Rose Engine meets Spirograph (YouTube video) by Pat Miller.

- Woodturning a box lid on the MDF rose engine using the @coolhammerman off-center chuck (YouTube video) by Q Branch Woodworks (Brad Bond).

|

Disclaimer: eMail comments to me at OTBookOfKnowledge @ Gmail.com. The process of woodturning involves the use of tools, machinery and materials which could cause injury or be a health hazard unless proper precautions are taken, including the wearing of appropriate protective equipment. |